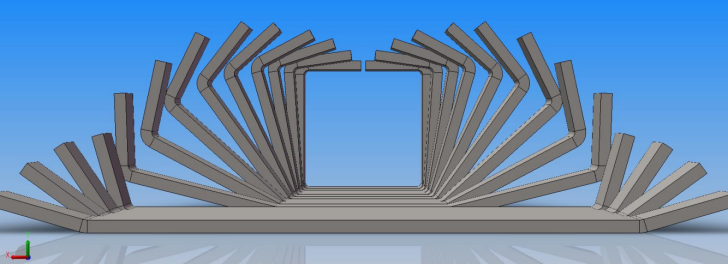

Direct square to square forming tube/pipe mill is use to produce size 60X60-150X150,wall thickness 2.5-10mm.

Categories: DFT/Direct Forming To Square Tube/Pipe Mill

Advantages

1.the motor adjustment roll opening and closing, lifting;

2.All the molds need not be replaced: only a set of rolls to produce all specifications;

3.When the specification is changed, it only needs to adjust the opening and closing of the mold, no longer needs to disassemble the partition; realize the mold sharing, and the roll adjustment of the whole line is completed by the motor to drive the worm wheel mechanism;

4.In the whole process of forming and setting the diameter, this forming process realizes the whole line without changing the rollers, which greatly saves the roll cost, improves the production efficiency, and reduces the labor intensity of the workers.

| MODELS OF DIRECT FORMING TO sQUARE TUBE MILL | ||||||||

| MODEL | QUARE TUBE O.D(MM) | RECTANGLE TUBE 0.D(MM) |

THICKNESS (MM) |

|||||

| DFS~60 | 20×20~60×60 | 25×20~80×40 | 0.8~3 | |||||

| DFS~100 | 30×30~100×100 | 35×30~120×80 | 1~4 | |||||

| DFS~150 | 50×50~150×150 | 60×50~200×100 | 2~6 | |||||

| DFS~200 | 80×80~200×200 | 90×80~250×150 | 3~8 | |||||

| DFS~250 | 100×100~250×250 | 110×100~300×200 | 4~10 | |||||

| DFS~300 | 150×150~300×300 | 160×150~350×250 | 5~12 | |||||

| DFS~400 | 200×200~400×400 | 210×200~450×350 | 6~16 | |||||

| DFS~500 | 250×250~500×500 | 260×250~550×450 | 8~20 | |||||

Products

© 2024 by FOSHAN JOPAR INTELLIGENT EQUIPMENT CO., LTD. All rights reserved Privacy Policy